Here is the YouTube video that gives a quick demonstration and a quick overview:

See the second post on this topic for diagram and improved code: TEA5767 FM Radio Receiver with Arduino Part TWO

Basically, the goal of this was to get a radio module to work with a microcontroller, and also decide on the amplifier configuration. In the video you can see it hooked up to a small 8 ohm speaker, and it sounds decent - and it will sound better once it is in an enclosure.

I purchased new potentiometers, the TEA5767 modules and the LM386 amplifiers off of eBay. Waiting for the components is a little frustrating, however the venders in China are low cost and very friendly - I've only ever had one issue, and it was the mail systems fault.

The most difficult stage of the project was trying to get the TEA5767 module to be useable. It is really really small. Don't order just one of these, you will likely make a mistake - I bought two of them for less than $4.00.

Attaching wires to this was tricky. This was my first attempt. in the bottom left, you can see a surface mount component is missing.. while attaching the wire with a soldering iron, I accidentally had solder run up onto the board and the component started to float - it was way too small to re-attach. The device no longer functions correctly, maybe I'll try to figure out what the component was at some point and fix it, but for less than two bucks, I'll let it go. Another issues I had, and this happened on both my modules, the bottom right pin is VCC, and I accidentally bridged it to the case of the crystal, which caused a short - easily fixed.

The second attempt was a little more involved, but yielded much better results! I used a scrap of protoboard and some pin headers to hold the chip. This technique was very similar to what I think I say someone else do while I was looking around on Google (I forget where). Basically, I just used a small piece of wire and threaded it through and pushed it against the side of the board and I soldered it from the side so I wouldn't damage components. I pushed the plastic down on the pin headers to get as much length as possible on the pins and dripped the header in. The wires are tacked onto the pins on the backside NOTE: You will need a clamp of some sort to dissipate heat when soldering the wires to the pins, as the heat will otherwise separate your wire from the side of the chip (I used a set of self clamping tweezers). One of the reasons why my breadboard was such a mess was because it was built to hold my first attempt, and the 2nd attempt didn't fit quite so nicely.

The first attempt would have taken less space, the second attempt didn't fit on the breadboard very well. Since I only had two of these, this will be how the module exists in my final clock project.

Most of the information I gathered on using the TEA5767 with an Arduino was on another blog:

http://www.electronicsblog.net/arduino-fm-receiver-with-tea5767/

This blog contains lots of information, including some information from the datasheet, it's highly readable!

Also on the breadboard is the LM386 amplifier. The speaker and amplifier circuit are all running off of the 5v rail on the Arduino board, which also goes to show how little power this takes. The schematic I used I found on another blog, Hack A Week, which I follow on YouTube regularly. His LM386 blog is found here:

http://hackaweek.com/hacks/?p=131

The schematic shows a 10uf capacitor to optionally increase gain, this circuit had plenty of overhead without it, so I didn't include it. I did the "bass boost" filter, but used 0.047uf rather than 0.033uf - I personally liked the sound more.

Here is a picture of on of my Arduino development boards for fun. You can see I'm only using a few wires. The Arduino had two wires supplying power to the breadboard, 2 wires for the I2C and one wire to receive ADC (analog to digital data) from the potentiometer being used as the tuner.

So yeah, watch the video at the top to see what's going on here. In the near future, I hope to have the tubes soldered onto a board so I can start moving ahead with the build. I have a few concerns about trying to multiplex 6 tubes with the same microcontroller that is running devices on an I2C bus, I might use two... I don't know, we'll see. But anyway, cheers!

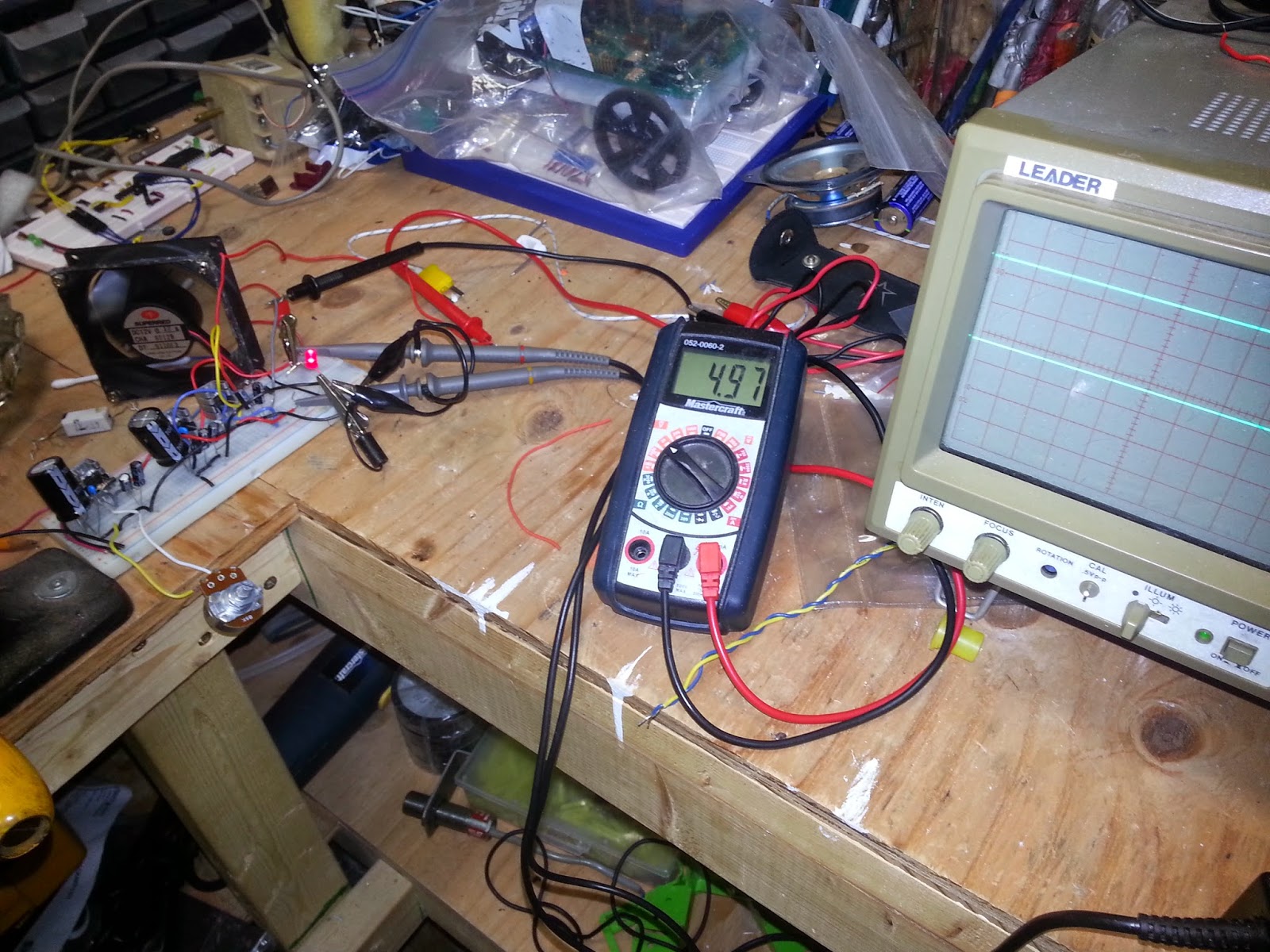

Here's a picture of what this project is doing to my poor workbench. A mess is a sign of genius, right?

Good luck with your project!